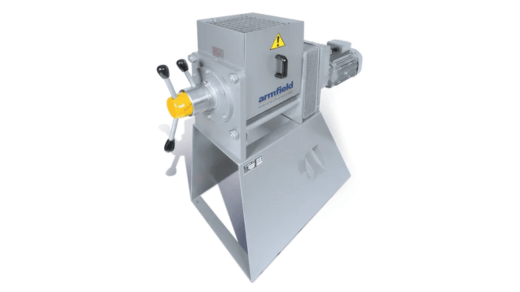

Oil Extraction Screw Press: A Small-Capacity Solution for Efficient Laboratory Use

In response to growing demand for efficient, small-scale oil extraction methods, the oil extraction screw press provides a powerful yet compact solution. Ideal for laboratory settings, this press for oil is designed to extract oil from seeds, nuts, and various fine biomass materials, making it a versatile choice for researchers and small producers. As the press extracts oil, it also forms a residual cake, which can undergo further purification for additional applications. This article explores the benefits, functionalities, and applications of this small-capacity oil extraction screw press, highlighting why it’s a valuable tool in laboratory environments and small-scale production.

The Growing Need for Small-Capacity Oil Extraction Solutions

As the demand for natural oils continues to rise in various industries—from culinary to cosmetics and pharmaceuticals—there’s an increased need for efficient extraction methods that don’t require large-scale equipment. For researchers and small-scale producers, traditional oil extraction systems are often too costly and complex for limited production needs. A small-capacity oil extraction screw press addresses this gap by providing an accessible, user-friendly solution designed for low-volume extraction without sacrificing quality or efficiency.

Key Features of the Oil Extraction Screw Press

The oil extraction screw press stands out for its simplicity, compact design, and effective performance, making it ideal for laboratory environments and small-scale operations. Here are some of its key features:

- Compact and Durable Design: Designed with laboratories and small facilities in mind, this oil press is compact, requiring minimal space. Its robust build ensures durability, allowing for consistent operation over extended periods.

- Versatile Applications: This press can extract oil from a variety of raw materials, including seeds, nuts, and fine biomass. Its adaptability makes it suitable for different oil types and research purposes, allowing users to experiment with various materials and techniques.

- Simple Operation and Maintenance: This oil press is intentionally unsophisticated, making it user-friendly for researchers and operators. It requires minimal maintenance, which is ideal for laboratory settings where ease of use is paramount.

- Cake Formation for Further Processing: During the oil extraction process, the screw press also forms a residual “cake.” This by-product can be collected and further processed for additional uses, such as animal feed, compost, or biomass fuel. The ability to repurpose the cake adds value to the extraction process, reducing waste and maximizing resource efficiency.

Applications of the Oil Extraction Screw Press

The oil extraction screw press is used in a variety of applications, especially in laboratory research and small-scale production. Here’s how different industries and research fields benefit from this equipment:

1. Laboratory Research

Researchers focused on oil properties, extraction methods, or material processing efficiency often use small-capacity oil presses. The compact screw press allows scientists to test extraction techniques on different seeds and biomass without the cost or complexity of large-scale equipment. By experimenting with various raw materials and extraction parameters, researchers can study oil yields, properties, and optimal processing conditions.

2. Cosmetic and Pharmaceutical Production

In the cosmetics and pharmaceutical industries, natural oils are valued for their purity and benefits in skincare, haircare, and health supplements. A small-capacity press enables producers to extract high-quality oils in controlled quantities, making it ideal for niche or experimental product lines. The oil press allows for minimal chemical interference, ensuring that the oils retain their natural composition—a key factor for these industries.

3. Nutritional Oil Production

Cold-pressed oils, derived from nuts and seeds like flax, chia, and sesame, are popular in the culinary industry for their health benefits and flavor. A small-capacity oil press is perfect for creating batches of fresh, unrefined oils that retain their nutrients and flavors. This makes it ideal for small-scale oil producers, artisan food manufacturers, and culinary researchers aiming to develop specialty oils.

4. Waste Minimization and Biomass Reuse

The residual cake produced by the press is a valuable by-product that can be repurposed in several ways. In the agricultural industry, this cake can serve as an organic animal feed or fertilizer due to its nutrient content. It can also be used as a source of biomass fuel, providing a renewable energy source and reducing waste. This makes the screw press a sustainable option for those focused on resource efficiency and environmental impact.

Benefits of Using a Small-Capacity Oil Extraction Screw Press

Adopting a small-capacity oil extraction screw press offers several advantages:

- Cost-Effective Solution: This press provides an affordable alternative to large-scale equipment, making it accessible for small businesses, laboratories, and independent producers.

- Eco-Friendly: By repurposing the residual cake, the press promotes sustainable practices and minimizes waste.

- Customizable Operation: The press allows operators to adjust parameters like pressure and extraction speed, enabling them to optimize the process based on the material and desired oil quality.

- High-Quality Extraction: With minimal heat involved, cold pressing preserves the natural flavors, nutrients, and qualities of the extracted oils, ideal for products that prioritize purity and nutritional value.

Conclusion

The oil extraction screw press is a valuable tool for those seeking a straightforward, small-capacity solution for oil extraction in laboratory or limited-production settings. Its versatility, ease of use, and efficient performance make it an ideal choice for extracting oil from a range of seeds, nuts, and biomass materials. As a practical, eco-friendly option, the screw press not only meets the demands of small-scale production but also contributes to sustainable resource management by producing a valuable by-product. With applications across various industries, from research to cosmetics and culinary production, this press supports the growing demand for high-quality, natural oils while prioritizing sustainability and efficiency.