PCBA Meaning and How LDRs Play a Role in Circuit Boards

When diving into the world of electronics, understanding the terms PCBA and LDR is crucial for anyone working with printed circuit boards (PCBs) and their assembly processes. This article will explain the meaning of PCBA and explore how Light Dependent Resistors (LDRs) contribute to the functionality of circuit boards.

What is PCBA (Printed Circuit Board Assembly)?

PCBA stands for Printed Circuit Board Assembly, a critical component in the electronics manufacturing industry. It refers to the process of attaching electronic components, such as resistors, capacitors, and integrated circuits, to a printed circuit board (PCB) using various techniques such as soldering and surface-mount technology (SMT).

The process involves several steps:

- PCB Fabrication: First, the PCB is created, usually from materials like fiberglass and copper. The board is designed to host electrical components, providing pathways for current to flow.

- Component Placement: After the PCB is fabricated, electronic components are placed onto the board, either manually or by automated machines.

- Soldering: This process secures the components onto the PCB. There are two primary methods of soldering: wave soldering and reflow soldering.

- Inspection and Testing: After the assembly process, the PCBA undergoes quality control checks, including functional tests and visual inspections.

PCBA is essential for nearly all modern electronic devices, from mobile phones and computers to medical equipment and automotive systems.

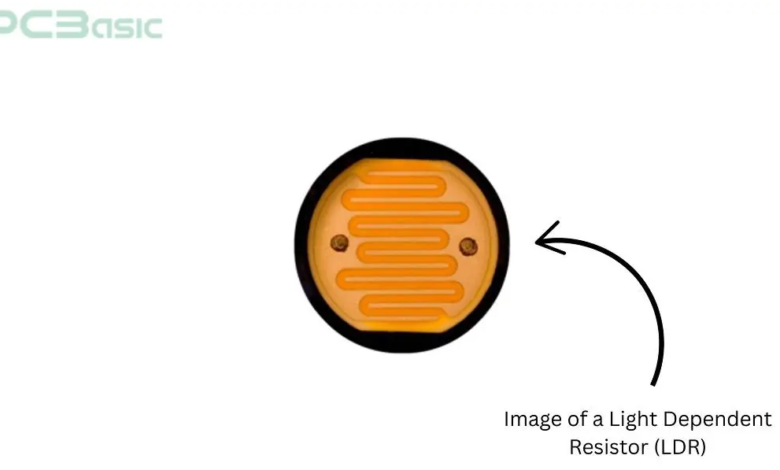

What is an LDR (Light Dependent Resistor)?

An LDR is a type of resistor that changes its resistance based on the amount of light it receives. LDRs are also known as photoresistors and are widely used in electronic circuits where light sensing is needed.

How Does an LDR Work?

LDRs are made of semiconductor materials such as cadmium sulfide (CdS). When light hits the surface of the LDR, it excites electrons, causing the material to conduct more electricity. This leads to a decrease in resistance. In the dark, the resistance of the LDR is high, and as light intensity increases, the resistance decreases.

LDRs are typically used in circuits where light is involved, such as:

- Automatic lighting systems: LDRs are used in street lamps and outdoor lighting that automatically turn on when it gets dark.

- Solar-powered devices: In solar-powered circuits, LDRs can help control when the device should operate based on available light.

- Alarm systems: LDRs are used to detect changes in light levels, such as in motion sensors and security systems.

Role of LDR in PCBA

In PCBA, LDRs can be integrated into various applications to enhance the functionality of the circuit. Their primary role in PCBA is to respond to changes in light conditions, making them ideal for:

- Automatic control systems: LDRs can control the switching of devices based on ambient light, contributing to energy efficiency and automation.

- Lighting control systems: In conjunction with other components, LDRs help automate light sensors, adjusting brightness levels in environments like street lighting and automated homes.

- Visual feedback systems: In devices like cameras and projectors, LDRs can be used to measure light levels for optimal performance.

Why is Understanding PCBA and LDR Important?

For those involved in electronics design and manufacturing, understanding PCBA and LDRs is crucial. The quality of the PCBA directly impacts the performance, reliability, and durability of the final product. Integrating components like LDRs ensures that electronic devices can interact intelligently with their environment, offering automation, energy savings, and improved functionality.

Conclusion

In summary, PCBA (Printed Circuit Board Assembly) is the backbone of electronic product assembly, and LDRs (Light Dependent Resistors) are a valuable component that plays a key role in light-sensing applications. By understanding the meaning of PCBA and the function of LDRs, you can better appreciate their significance in creating reliable, efficient, and functional electronic devices. Whether you’re involved in design, manufacturing, or quality control, this knowledge is essential for creating high-performing electronic products.